Welcome

at Fischer Spezialbaustoffe

Fischer Spezialbaustoffe GmbH develops and produces thermally optimised grouting materials/backfilling materials for the grouting of geothermal probes.

The Fischer GeoSolid® range of products have a high thermal conductivity, a proven freeze-thaw resistance and other improved physical properties. The grouting material of Fischer GeoSolid® 240HS is also suitable for use with sulphate-aggressive groundwater.

Our Products

An overview of all building materials

The grouting or backfilling of geothermal probes is an important and necessary step for the safe installation and efficient operation of geothermal systems. In addition to the professional execution of the grouting work, the properties of the backfill material play an important role.

Fischer Spezialbaustoffe GmbH provides the geothermal energy industry with the products of Fischer GeoSolid® series, a thermally optimised and high-quality grouting material that meets today’s requirements regarding safety, workability and durability.

Fischer GeoCompact®

Grouting material for geothermal probes, wells and underground engineering

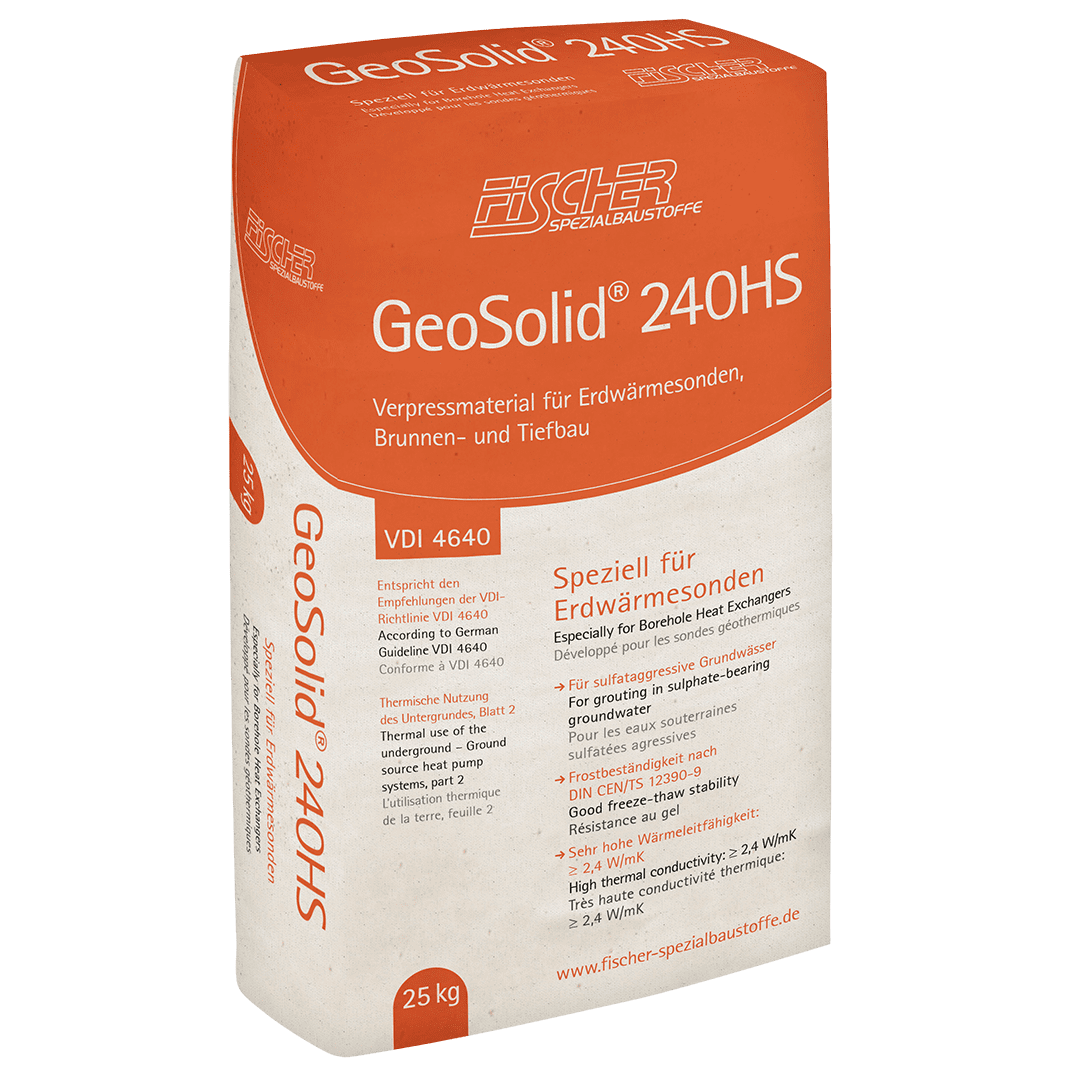

Fischer GeoSolid® 240HS

For geothermal probes in sulphate-aggressive groundwaters

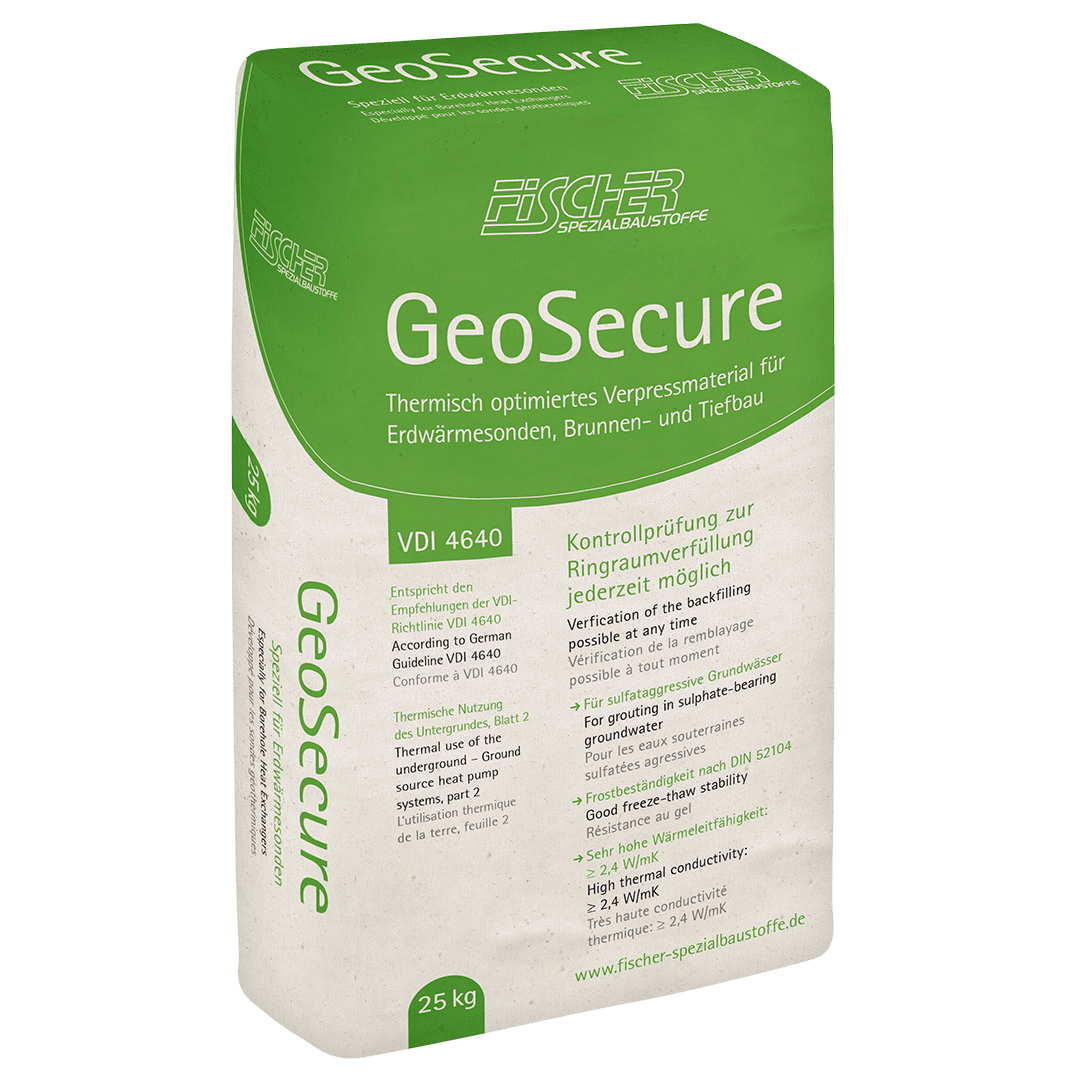

Fischer GeoSecure®

Thermally optimised, magnetically doped grouting material

Fischer GeoFlow®

Very efficient grouting material with effective thermal conductivity

Fischer GeoFlow IQ®

Magnetically doped, very efficient grouting material with high thermal conductivity

Fischer GeoTight®

Inexpensive grouting material for backfilling of the cavities

References

Here you will find an extract of our projects.

Contact

If you have any questions about our products, we are happy to assist you. You can also use our form for praise, criticism and suggestions.

We are looking forward to your message!

Fischer Spezialbaustoffe GmbH

Gutenbergstraße 4

91560 Heilsbronn

Germany

Tel.: +49 9872 953999-0

Fax: +49 9872 953999-9

FAQ´s

The large borehole annulus should be tightly and permanently backfilled to protect the pipes, to ensure good heat transfer from the rock to the pipes and finally to the circulating water-glycol fluid („brine“) and to stabilize the borehole wall.

For reasons of groundwater protection, the incursion of surface water should be prevented and a seal should be made between two different groundwater levels (Note: This case does not apply to Bavaria, where only drilling in the 1st groundwater level are permitted).

Thermal conductivity describes the material property of a material. The thermal conductivity has the unit Watt per Kelvin and meter (W/m*K) and describes how well thermal energy is transferred through a material.

With high thermal conductivities, thermal energy is transferred very well. This results in good system efficiency in geothermal systems and ensures good heat transfer in heating mode and rapid dissipation into the surrounding soil in cooling mode.

It must be post grouted if the suspension in the borehole sinks due to crevices or groundwater flow. This post grouting can be prevented with high quality grouting materials with corresponding high densities – e.g. the products of the Fischer GeoSolid® series. Furthermore, a good, homogeneous mixing of the grouting material also helps.

The freeze-thaw resistance change is important for the grouting material with regard to system operation. Possible frost actions result from the circulation of supercooled (temperatures below 0°C) water-glycol mixtures („brine“) and not due to the frost actions from the surface of the terrain (Note: The geothermal heat pipes have placed the frost-resistant below the natural frost incursion limit at approx. 1-1.5 m below ground level ).

The Freeze-thaw resistance change in building materials, such as Fischer GeoSolid® products, are not damaged by the temperatures occurring in the geothermal probe pipes by freezing excess water or ground water in the pores. This property is important to have a durable and stable backfill material around the geothermal probe in the borehole.

The borehole resistance is determined as a measured value in the so-called Thermal Response Test (TRT), which is carried out as a test on a geothermal probe at the planned plant location.

The borehole resistance consists of a value that is influenced by the probe geometry, the thermal properties of the grouting material and the influence of disturbances (possibly existing groundwater). Thermally improved grouting materials are favourable because it reduce the resistance of the borehole.

A high-quality grouting material prevents the leaching of harmful substances and their entry into the groundwater or the soil through good environmental compatibility.

Due to its good long-term stability (against frost effects from the geothermal probe or cementitious materials in the groundwater), it ensures a good connection of the probe pipes to the surrounding soil. The incursion of surface water is prevented, thus ensuring the protection of groundwater. The use of thermally improved grouting materials increases system efficiency by reducing the resistance between the borehole wall and the probe pipes. This ensures a better heat transfer.

Using one or more injection hoses or an injection rod, the suspension is first mixed in a mixing system and then pumped into the borehole. This is done in the so-called contractor procedure from bottom to top.

This is to ensure that any groundwater present in the borehole is displaced upwards or sideways and the entire borehole is filled with a suspension of the same density. This density is controlled during the grouting process. The grouting is completed when the grouting suspension comes out of the borehole at the same density on the surface as it is pumped into the borehole.

They are mixed with a suitable mixing pump, which can mix continuously or in batches. An optimal result is obtained with a colloidal mixer.

Damage to geothermal boreholes has recently been caused by unprofessional work during the construction of geothermal probes or due to difficult geological and hydrogeological conditions.

If the grouting material is used professionally, unfavourable geological conditions can be compensated under certain circumstances (e.g. safe closure of a borehole in which pressurised groundwater rises to the surface).

There are, however, geological conditions in which the construction of geothermal probes should generally be avoided. If problems occur during the construction phase, a balance must be achieved so as to check whether these can be controlled with professional technology or whether drilling must be stopped. The decision on this is made by the approval authority.